In this article, the following types of flanges are covered.

- Threaded Flanges

- Socket-Weld Flanges

- Slip-On Flanges

- Lap Joint Flanges

- Weld Neck Flanges

- Blind Flanges

- Reducing Flange

- Expander Flange

- Flangeolet / Weldoflange / Nippoflange

The pipe flanges are the second most used joining method after welding. They are used when joints need dismantling. It provides flexibility for maintenance. Flange Connects the pipe with various equipment and valves. Breakup flanges are added to the pipeline system if regular maintenance is required during plant operation.

A flanged joint comprises three components; flanges, gaskets, and bolting and assembled by pipefitter. Special controls are required to select and apply all these elements to attain a joint, which has acceptable leak tightness.

However, it is not advisable to use a flange connection in underground piping when it supposed to be buried. The flange is also the most common source of leak and fire in a process plant. There are a variety of flanges available to suit the requirements. A flange can be classified in several alternate ways based on the following:

- Types of Connection

- Flange facing Types

- Pressure-Temperature Ratings

- Material Types

Threaded Flanges

Threaded Flanges are also known as screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. This type of joint connection is speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water.

- Threaded Flange mostly used in utility services such as air and water

- It is not suitable for high presser and temperature applications

- It also available in limited Size of NPS 4” and below

- Threaded Flanges can be FF or RF

- It is a Low-cost flange.

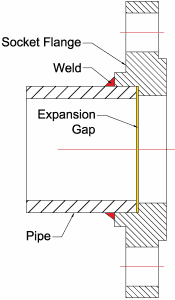

Socket-Weld Flanges

Socket-Weld Flanges has a female socket in which the pipe is fitted. Fillet welding is done from outside on the pipe. Generally, it is used in small bore piping and only suitable for low pressure and temperature application.

- Socket-Welded Flanges can be FF or RF

- The cost of flange and fabrication is moderate.

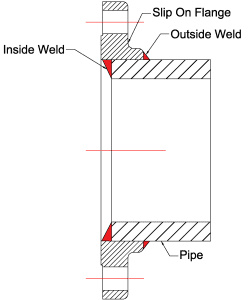

Slip-On Flanges

Slip-On flange has a hole with matching outside diameter of pipe from which pipe can pass. The flange is placed on pipe and fillet welded from both inside and outside. Slip-On Flange is suitable for low pressure and temperature application.

- This type of flange available in large size also

- It can be FF or RF

- The cost of flange and fabrication is moderate.

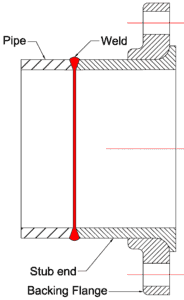

Lap Joint Flanges

The lap flange is having two components, a stub end, and a loose backing flange. The stub end is butt-welded to the pipe, and the backing flange freely moves over the pipe. The backing flange can be of a different material than stub material and normally of carbon steel to save the cost. Lap flange is used where frequent dismantling is required and space is constrained.

- The backing flange can be of a different material than stub material and normally of the carbon steel to save the cost.

- This flange provides better joining due to butt-weld as compared to a socket and threaded type flanges

- Not suitable for small size, Costly components, and fabrication as compared to threaded, slip-on, and socket flange.

- Lap flange provides connection flexibility as you can freely rotate the flange on the pipe. It is used where frequent dismantling is required, and space is constrained.

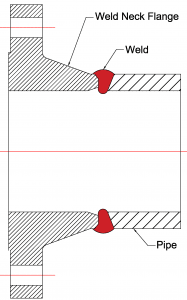

Weld Neck Flanges

Weld neck flange is the most widely used type in process piping. It gives the highest level of joint integrity due to Butt-welded with a pipe. These types of flanges are used in high pressure and temperature application. Weld neck flanges are Bulky & costly with respect to other types of the flange.

- High skill is required for fabrication and also required more space to accommodate in the piping system due to the long hub.

- Weld Neck Flange is available in all sizes & it can be FF, RF or RTJ type

- You can see the Weld Neck flange welded with pipe

Blind Flanges

The blind flange is a blank disc with a bolt hole. These types of flanges are used with another type of flange to isolate the piping system or to terminate the piping as an end. Blind flanges are also used as a manhole cover in the vessel.

Reducing Flange

Reducing flange is used in place of a standard flange to allow for a change in pipe size. This flange eliminates the need for a standard reducer in piping. The flange consists of one specified diameter with a smaller diameter bore size.

Except for the bore and hub dimensions, a reducing flange has dimensions of the standard pipe flanges size and is considered an economical means to make a pipe size transition.

These flanges are available in weld neck, slip-on, and threaded end types. Reducing flanges are an economical way to make transitions between pipes of different sizes, however, due to high-pressure loss, they are rarely used in piping. ASME B16.5 covers the dimensions of reducing flanges.

Image source: www.msmmfg.com

Expander Flange

It is similar to a weld neck flange but increases the size of the pipe to the first or second larger size. It is an alternative to using reducer and weld neck flange. Useful for connecting to valves, compressors, and pumps.

These flanges are specially designed. Dimensions of the weld neck are in line with the connecting pipe, other dimensions are in accord with standard ASME B16.5 flanges.

Image source: www.msmmfg.com

Flangeolet / Weldoflange / Nippoflange

Flangeolet is a combination of olet (mainly weldolet or nipple) and flange. As you can see in the image that hub length is longer like long neck weld flange. It is a 90 Degree branch connection use for high-pressure piping.

It reduces the two weld joints than the traditional Olet + Pipe + Flange connection and one weld joint in case of Olet + Flange connection. You can see the image of the flangeolet branch.

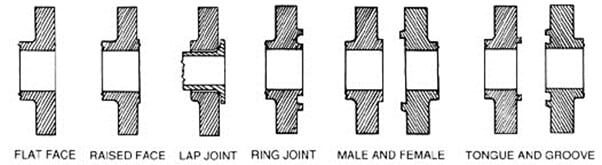

Types of Flange Based on the Face

Depending on the flange facing Types, it can be further classified as

- Flat Face (FF)

- Raised Face (RF)

- Ring Joint (RTJ)

- Tongue and groove (T&G)

- And Male and Female type

Flat Face

As the name suggests, the flat face flange has a flat face. Flat face flanges are used when the counter-flanges are flat face. This condition occurs mainly in connection to Cast Iron equipment, valves, and specialties. Full face gasket is used when a flat face flange is used.

Raised Face

Raised face flange has a small portion around the bore is raised from the face. The gasket seat on this raised face. The height of the raised face depends on the flange pressure-temperature rating that is known as a class of the flange. For 150# & 300# height of the raised face is 1/6” and above 300# it is 1/4”. The inside bore circle type of gasket is used with a raised face flange.

RTJ Face

Ring joint type face flange has a specially designed grove in which metal gasket seat. This type of flange is used in high pressure and temperature services.

Flange Materials

Flanges are manufactured from following materials

- Carbon steel

- Low alloy steel

- Stainless steel

- Combination of Exotic materials (Stub) and other backing materials

The list of materials used in manufacturing are covered in ASME B16.5 & B16.47.

- ASME B16.5 -Pipe Flanges and Flanged Fittings NPS ½” to 24”

- ASME B16.47 -Large Diameter Steel Flanges NPS 26” to 60”

Commonly used Forged material grads are

- Carbon Steel: – ASTM A105, ASTM A350 LF1/2, ASTM A181

- Alloy Steel: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

- Stainless Steel: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Flange Inspection

During an inspection you have to check the following;

- Outer & Inner Diameter of body

- Bolt Circle & Bolt hole Diameter

- Hub Diameter & thickness of weld end

- Length of the Hub

- Straightness and alignment of the bolt hole

ASME B16.5 and B16.47 standards covers permissible tolerances for inspection.

Marking on the Flange Body

Marking of flange must includes the following;

- Manufacturer logo

- ASTM material code

- Material Grade

- Service rating (Pressure-temperature Class))

- Size

- Thickness (Schedule)

- Heat No

- Special marking if any QT (Quenched and tempered) or W (Repair by welding)