Technical Note PP 811-TN

PE Flange Connections

Flange Connection

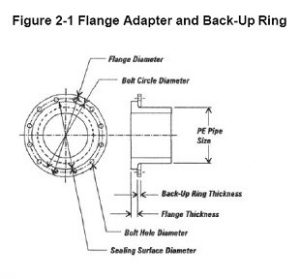

Flanged joints are made using a DriscoPlex® Flange Adapter that is fused to the pipe then joined to a mating flange adapter or a mating appurtenance flange. A back-up ring is fitted behind the flange adapter’s sealing surface flange as shown in Figure 2-1 and bolted to the mating flange. DriscoPlex® Flange Adapters have a serrated sealing surface. At lower pressure, typically 100 psi or less, a gasket is usually not required. At greater pressure, the serrations help hold the gasket in place.

The back-up ring is required for polyethylene flange joints in order to develop uniform pressure around the entire sealing surface. Without a back-up ring, a polyethylene flange will leak between the bolts. Standard back-up rings are convoluted ductile iron with AWWA C207 150 lb drilling. Other available back-up ring materials are steel, primer-coated steel; epoxy coated steel, stainless steel or fiberglass. In below ground service, coatings and cathodic protection may be needed to protect metal back-up rings from corrosion. One edge of the back-up ring bore must be radiused or chamfered. This edge fits against the back of the sealing surface flange.

Service pressure ratings for back-up ring designs and materials will vary. Consult the back-up ring supplier for the maximum recommended rating. The service pressure rating for the back-up ring should meet or exceed the service pressure of the pipe. Typically, back-up rings are ANSI Class 125 for gravity applications, ANSI Class 150 or AWWA C207 for pressures up to 267 psi (200 psi for 20” to 24” sizes), and ANSI Class 300 for higher pressure.

Flange adapters are long enough so that they can be clamped in a fusion machine like a pipe end. The back-up ring is fitted to the flange adapter before fusion, so external fusion bead removal is not required.

Click link(s) below to print, download and view the details